Solution – Predictive Maintenance & ML | Servitization

Get the crystal ball in the machine shop. We are going for ZERO unplanned downtime!

Zero unplanned downtime! Important subjects for Servitization are about availability (uptime), performance, quality, sustainability, and security. ‘High-quality maintenance’ is an important activator for this, which needs to be supported by a real-time Machine-2-Machine connection. Predictive Maintenance (PdM) is a tool that needs to be integrated into your architecture and processes, to gather valuable real-time maintenance data.

However, this type of control has many advantages;

- Effective preventive maintenance planning, get improved condition-based (CBM) insights

- Quick possible change from a reactive to a proactive culture

- Increasing control over critical parts and sub-components

- Improved spare parts control

- Reduction of design & manufacturing issues

- Improved uptime, performance and quality control

- Control about valuable historical data

- Improved utilization and cost control

We see Predictive maintenance as a very helpful solution to reshape your strategy for Servitization (maintenance and asset management). It’s important to know your actual Maturity, so you are able to handle this ‘Crystal Ball in the Machine shop’. See the indicator of that Crystal Ball below.

We offer flexible PdM software systems that are fitting for your product. In our opinion, it’s very important, that you remain the owner of your data, at your own chosen data warehouse. This next-generation Predictive Maintenance software needs, No new sensors, No hardware. Just create value in a better way of analysing data. It’s important to consume, supervise, Collect and Learn any unstructured and structured data that is gathered from the product.

Below are the mentioned ‘triggers and sensors’ that can gather data and are used for these analyses. Below in green you find the unique criteria of this PdM application that align mutual activities.

#Pressures #Temperature #Vibration #Flows #Valve status #Tank levels #Resistor tags #Delta pressure tags #Hours #Ambient temperatures #Other collected data

- Alerts are clear, accurate, and early enough to define actions.

- No overflow of alerts, acceptance of alerts is good enough for the control team.

- Insights into the overall system health.

- Dead sensors are counted as well.

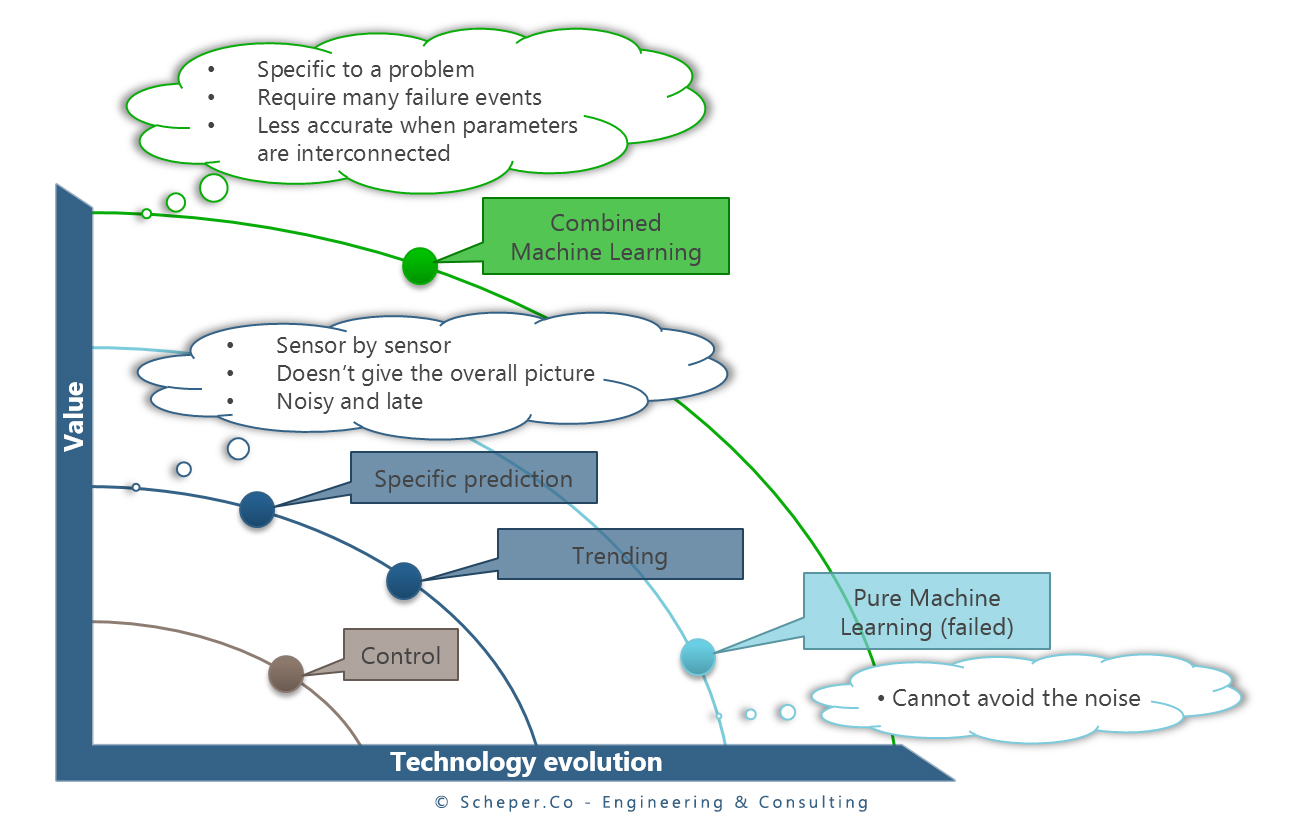

Predictive analysis tries to answer the question ‘what might happen in the future?’ Our Predictive Maintenance software (PdM) is a combination of Cognitive Intelligence & Machine Learning (ML). It will give an early pin-point alert of your problems, so you can take action.

Inspired? It is time to evolve! Check out for more, we’d like to hear from you.

Contact Scheper.CoEmpower You Services Scheper.CoSupercharge Strategy