Gravity Pressure Vessel | GPV

Empowered Solution for a Profitable, Clean & Sustainable Community

GPV reactor design and engineering | Well engineering (with SodM standards) | Drilling/Installation program GPV (Bio Rights) | Design and engineering GPV installation | Tendering of the complete GPV system | Business re-engineering (Since 2016)

Customer

GeneSyst Europe | www.genesyst.com

Sector

Energy Industry

Period of Execution

- Start: 2012

- Finish: 2015

- Stakeholder: 2015 – 2018 | Project manager R&D GeneSyst EU

Methods, Techniques, Tools

Product design | Mechanical Engineering | System Engineering | Drilling Engineering | Well Engineering | Well Design | Geology study | SHEQ control | Project management | Business Development | Value Engineering

Value added elements

- Drilling companies

- Staatstoezicht op de Mijnen (SodM)

- Construction companies

- Manufacturer special equipment

- System suppliers

Company overview

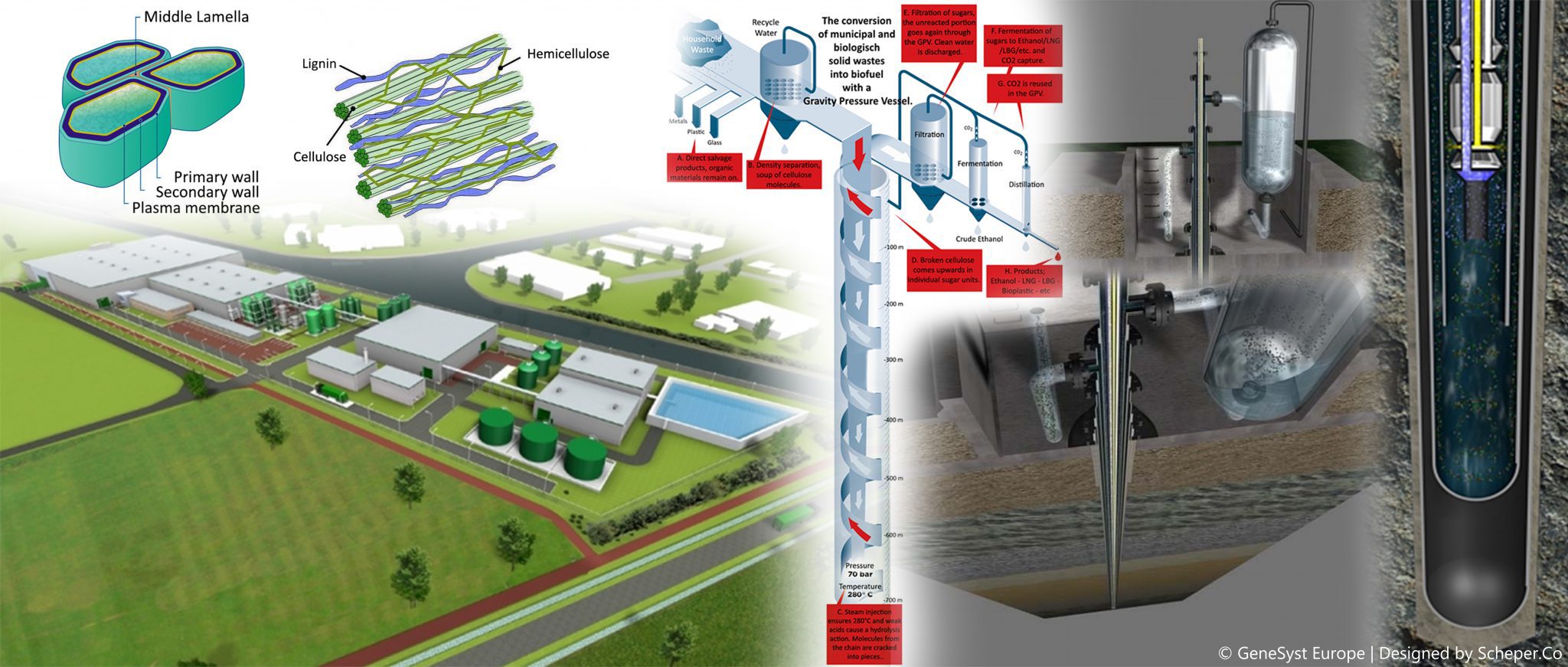

GeneSyst International, Inc. is the exclusive licensing source for a unique combination of patents and proprietary technologies for converting waste to energy, utilizing the Gravity Pressure Vessel (GPV). Waste can be converted to an asset, not a liability. By using proprietary GPV technology, you have a profitable, self‐sustaining, and financially self-replicating enterprise that generates, high-value fuels and materials, keeps local resources within the community and ensures a clean environment for all.

Technology challenge

Today we can build a cleaner community, by converting wastes into renewable, profitable products, such as biofuels, ethanol, butanol, methane, and yeast protein. For this, we use biomaterials/fibres which are not suitable for consumption. In these fibre materials lignin closes the C5 (hemicellulose) and C6 (cellulose). These C5 and C6 (sugars) are located in;

inter alia, wood, paper, sheet, manure, municipal waste types, etc. To convert C5 and C6 sugars, the lignin must be cracked. High pressure and high temperature can crack this lignin. The GPV process is highly exothermic, temperatures quickly rise up to 280+ Celsius and the Vessel is freely hanging inside an external shaft under a vacuum seal at depths of 750 metres below the surface. The challenge, develop a reactor and GPV which is suitable for the required specified conditions. The main facing challenges; are vertical straight installed reactor, sustainable and high-quality materials that are resistant, meeting operational drilling standards and relatively easy maintainable GPV installation.

Why Scheper.Co?

Empower Your Future. Scheper has a deep understanding of alternative drilling/service techniques. Combined with a background in process technology (TU Delft – 3ME) and smart ideas for the reactor design. His input has formed a solid combination to convert this concept into an operational prototype. Together with different specialists, Scheper offered a sustainable GPV solution. (TRL 5).

How Scheper.Co helped?

We have added a blend of our Services (Strategic Management, Project Management and Product Development). We developed a system for the reactor construction (750m depth) and developed additional also the next generation GPV, which is assembled out of different (static & dynamic) parts, which can be operated reliably, cheaper and more sustainable.

Customer quote

“Profitable, Clean & Sustainable” Scheper did an excellent job for the location of Biorights Hardenberg by the tendering, well engineering and a drilling/installation program. This complete project meets the SodM (Staatstoezicht op de Mijnen) standards and is carried out with smart drilling technologies. Additionally, Scheper developed for GeneSyst EU the next generation GPV, compiled with smart components and materials that can be exposed to highly exothermic temperatures, high pressures, and chemical process environments.

Video | Gravity Pressure Vessel operation

Download free sheet

Inspired? It is time to evolve! Check out for more, we’d like to hear from you.

Contact Scheper.CoEmpower You Services Scheper.CoSupercharge Strategy