Predictive Maintenance | Servitization

Empowered Solution for Servitization

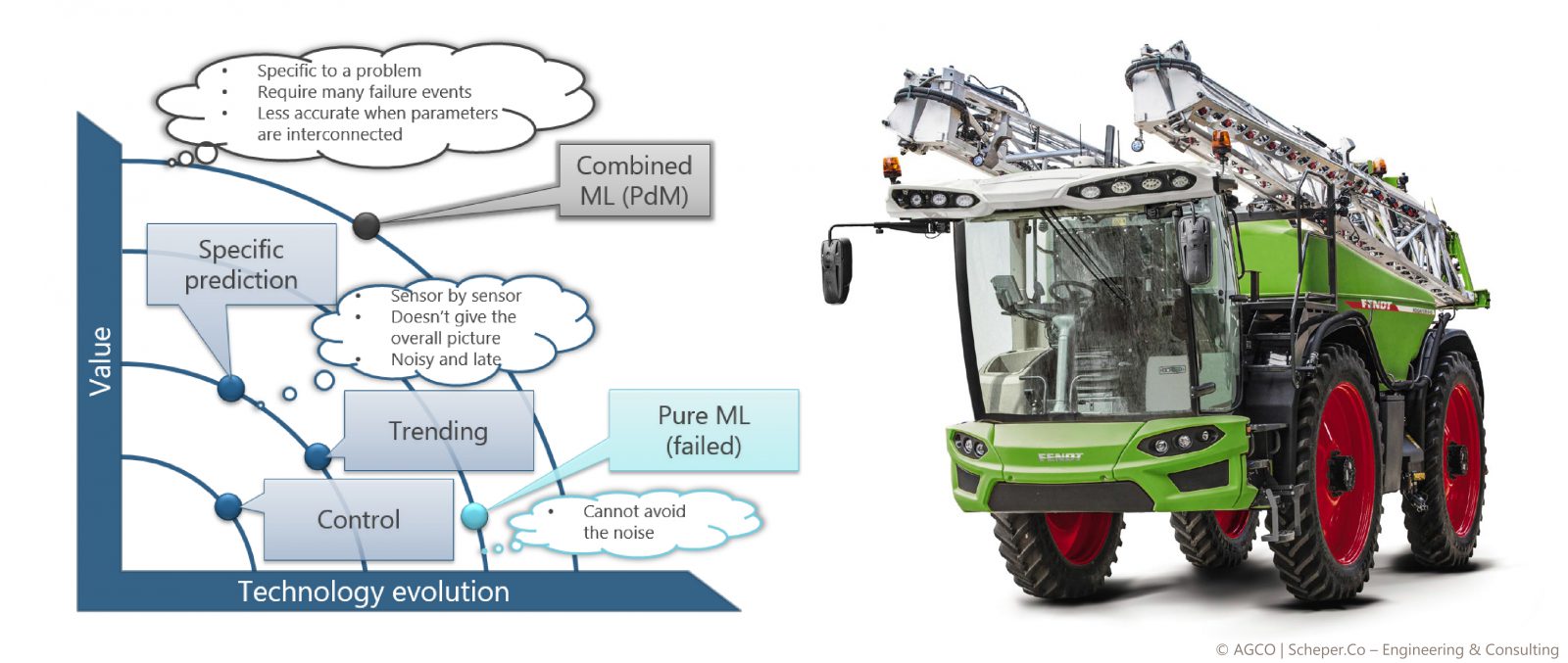

Predictive Maintenance (PdM) | Machine Learning (ML) | Cognitive Learning (combined ML) | Scalable PdM solution | Dedicated pin-point analytical PdM solution

Customer

AGCO | www.agcocorp.com

Fendt | www.fendt.com

Sector

Smart Industry

Period of Execution

- Start: May 2019

- Finish: Frozen in 2020, during Covid-19

Methods, Techniques, Tools

End-2-End Predictive Maintenance software

Value-added elements

- PdM Pilot with an Israeli partner company

Company overview

Fendt is not just a name, Fendt is a conviction. With Fendt tractors and harvesting machines, farmers and contractors can reach their goals faster and with a higher yield. Power. Performance. Efficiency. Innovation! The Fendt brand offers leading products to make farmers more successful. Fendt is building exceptional machines, products, and services for farmers, so farmers can harness their own passion to produce excellent quality with maximum efficiency.

Pilot challenge

Can you provide us necessary advanced analytical power for PdM? We are interested in your solution, that differentiates from the current landscape. We would like to build a scalable solution, suitable for 60.000 machines annual. This is necessary to decrease downtime and unplanned repairs. Please, include for this pilot analytics, support, subscription, integration, and installation.

Why Scheper.Co?

Scheper.Co turbocharged our subject matter experts based on their experience about agricultural machinery and industry knowledge with Servitization within the PoC. AGCO would like to start a pilot together for Predictive Maintenance, which is an important enabler for Servitization.

How Scheper.Co helped?

We provided based on our Strategic Management Services a dedicated pin-point solution to predict failures (tiny changes within machines) and identify abnormal operation for predictive maintenance by advanced analytics and AG-machine expert knowledge. No new sensors, No hardware, Just create value by a better way of analysing data. Alerts are clear, accurate and early enough to define actions, with no overflow of alerts and very valuable insights about the overall machine health (lifecycle).

We tried to answer the question “what might happen with the technical machine condition in the future?” For this, we provided a pilot together with our Israeli partner company, based on an End-2-End Predictive Maintenance solution. This solution is specific mentioned for AGCO’s application machines and starts with the Fendt Rogator (self-propelled sprayers). The software is scalable for the entire AGCO fleet based on, an average price per hour and the estimated total number of tags (sensors, trigger, etc.). For the customer, we can ensure with this solution the highest uptime, within the full life-cycle of each machine.

Customer quote

High-tech solutions for professional farmers feeding the world. “Profitable growth through superior customer service, innovation, quality, and commitment”.

Download free sheet

Inspired? It is time to evolve! Check out for more, we’d like to hear from you.

Contact Scheper.CoEmpower You Services Scheper.CoSupercharge Strategy